Application process of dissolving cryogenic centrifuge

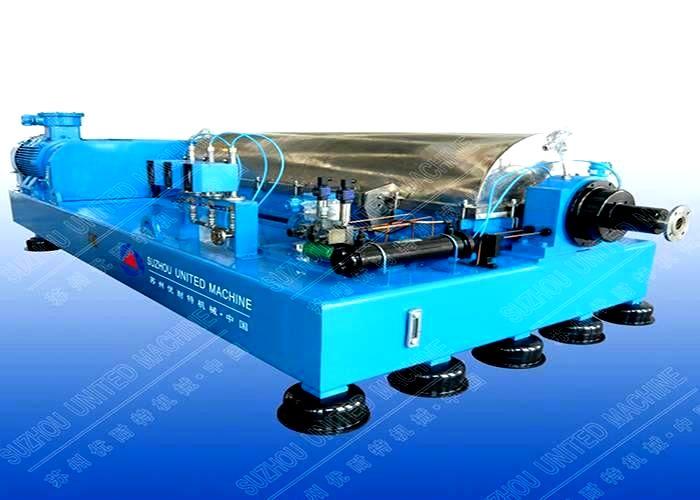

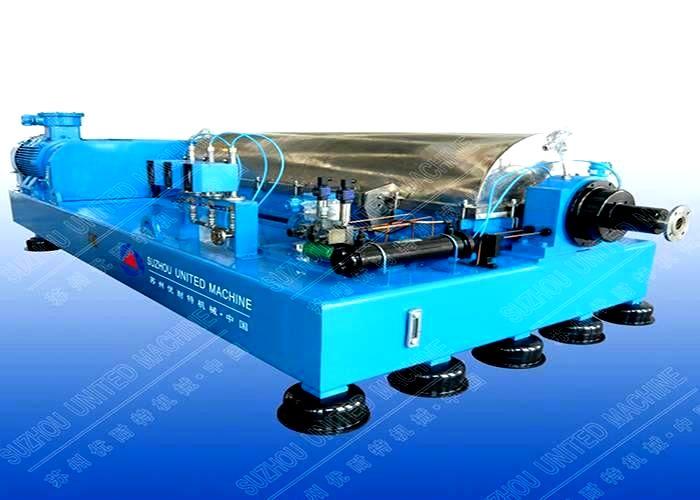

Low temperature centrifuge is one of the key products of our company. The key products are low-temperature high-speed centrifuge and low-temperature low-speed centrifuge. This centrifuge is controlled by microcomputer, touch control panel, LCD, variable frequency motor driver, stable operation, imported refrigeration compressor unit from Europe, and 10 kinds of environmental protection refrigerant, The main parameters can be changed anytime and anywhere during the operation without the action of power-off inching. The transient suction filtration can be compatible with a variety of volume motor rotors and a variety of power adapters.

1、Before using the low temperature centrifuge, it can be applied after the willingness of the management personnel, and the application record of relevant instruments and equipment shall be well done.

2、According to the relative density of the test sample, the same volume geostress of the test sample should be 3 mm away from the test tube mouth.

3、Put the centrifugal pipe with the same relative density and dry wall thickness into the bucket, tighten the bucket cap, and hang it on the matching bucket rack. Note: if the bucket is empty, it can also be suspended.

4、Turn on the main power switch of the low-temperature centrifuge, step on the pedal with your feet, and press the specific part with your hands, the door cover will open automatically.

5、Straighten the swivel of the suspension bucket down and carefully place it on the rotating shaft sleeve to ensure its firmness. Tighten the swivel cover and press the door cover down by pressing the specific part.

6、Set the main parameters of centrifuge suction filtration, including: model and specification of rotating head, speed ratio, temperature, time, elevator speed frequency, etc. until the basic parameters are correct, press the start button.

7、In the whole process of the application of cryogenic centrifuge, the user should pay attention to the application of the centrifuge immediately. When the speed ratio of the centrifuge is set to five minutes, the user can leave.

8、After the filtration, the door opening cover can be opened until the rotating head is stopped. The swivel head cover shall be loosened and the swivel head shall be taken out and put on the special shelf.

9、Take out the bucket, loosen the bucket cap, and take out the sample. The bucket and bucket cap should be pulled apart and put on a specific part. If there is leakage, take out the sealing ring, clean it and put it upside down on the table cloth.

10、After the operation of the cryogenic centrifuge is completed, the switching power supply of the instrument and equipment should be turned off immediately, and the condensed water in the chamber body should be cleaned. It should be noted that the centrifuge door cover can be turned off only when the temperature of the inner chamber is the same as that of the room.

National Service Hotline

National Service Hotline

National Service Hotline

National Service Hotline